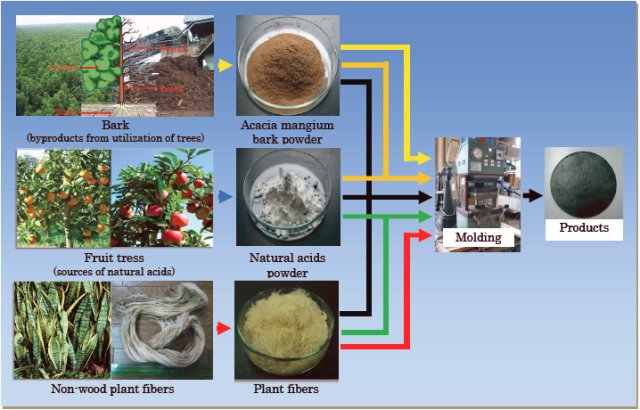

Renewable resources offer an attractive way out of the impending economic and obvious ecological problems for the chemical sector over the next two to three decades. Some renewable resources i.e. bark and plant fibers have been used as material in the field of molding production.

As byproducts from utilization of trees on the production of pulp paper and boards, bark is very potential raw material. Recently, the utilization of bark is subjected for the production of tannin (adhesives) for wood composite. On the other hand, plant fibers with low cost, high performance and lightweight materials have been used to replace pure synthetic polymer such as PP, PET, and PVC on the production of plastic molded products.

In order to reduce the utilizing of synthetic polymers and produced environmental friendly products, recently, natural acids that obtained from plantation and used as curing accelerator and a binder on molding production have been the object of intensive academic and industrial research.

Improving the performance of bark and fiber molded products have been carried out by adding natural acids. It’s because the cross-linked bonds are between carboxylic acid groups of natural acids and hollocellulose chain of bark and fibers. Also, natural acids reduced the optimum pressing temperature on the production of acacia bark molded products. These products can ultimately be used as automotive body parts, packaging materials, furniture parts and household products.

The ultimate goal is developing and characterizing molded products made from bio-based renewable resources having applications promising for making human-live improvement and save the nature.