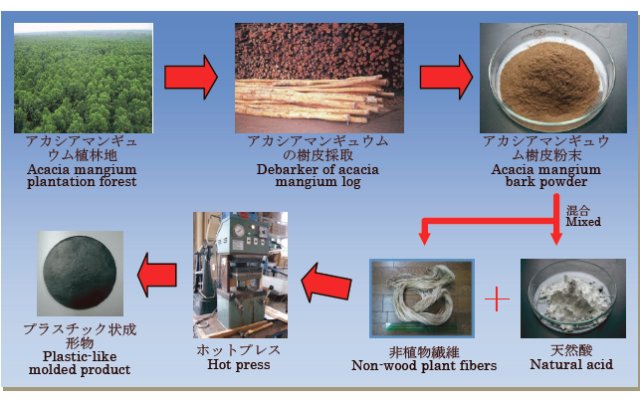

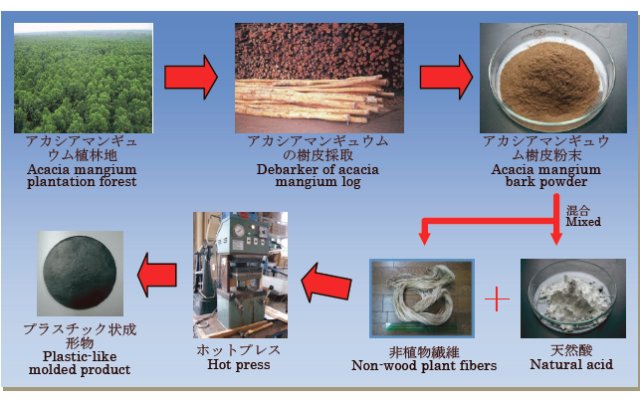

Development of new plastic-like molded products from acacia mangium bark and natural acid reinforced with non-wood plant fibers Development of new plastic-like molded products from acacia mangium bark and natural acid reinforced with non-wood plant fibers

非植物繊維で補強したアカシア樹皮と天然酸によるプラスチック状成形物の開発

平成20 (2008) 年度ミッション専攻研究員

Sasa Sofyan Munawar

Acacia mangium Wild belongs to the most important wood species as raw materials for the pulp and paper industries. Acacia mangium Wild is mostly used for the development of timber estate of fast growing tree species. During the production of pulp and paper or medium density fiberboard (MDF), the raw material of wood has to be debarked to remove the bark layer, because bark in the pulping decreases the pulp quality. Thus, the barking waste (bark) in those factories is very potential raw material. Recently, the utilization of bark waste from pulp or MDF factory is subjected for the production of tannin (adhesives) for wood composite (Roffael 1976, Pizzi 1980, Chen 1991, Prasetya and Roffael 1991).

Generally, the utilization of various tannin from wood or bark for wood adhesives has been proposed by many authors from different countries (Pizzi 1983), Yazaki 1985, Long 1991, Zhao et al. 1994, Lu et al. 1995, Vazquez 1996, Yano 2001). Many efforts have been done to enhance the gluing ability of tannin by chemical modification such as utilization of phenol, resorcinol, melamine, lignin sulfonate, amine compound and sodium sulfite (Long 1991, Dix et al. 1987). However, addition of chemical substance on the utilization of tannin as wood adhesives increases environmental problems.

Currently, the utilization of acacia mangium bark as raw material for molded products was explored. Natural acid used to accelerate the curing process of molded products and to increase of its dimensional stability and mechanical properties. The mixed of acacia mangium bark and natural acid hence facilitating production of the products from 100% renewable resources. Preliminary experiments showed that the acacia mangium bark and natural acid are well mixed for plastic-like molded products considering the temperature and pressure at hot pressing conditions.

On the other hand, utilization of high strength’s non-wood plant fibers to reinforce of those plastic-like molded products has not been investigated and it can be predicted to have good physical, mechanical and thermal properties. Those results can ultimately be used as a source of high-performance composite to the human-live improvement not only in Japan but also in other countries, where the green polymers can be reduce the utilizing of synthetic polymers.

|