Flagship Collaborative Research "Bio-nanomaterial research"

Updated: 2017/10/18

Project Outline

Bio-nanomaterial research

Leader:Hiroyuki Yano

In this flagship research, we perform collaborative fusion research for the production and reconstitution of cellulose nanofibers to contribute to the establishment of a sustainable humanosphere through the creation of advanced bio-based nanomaterials for use in automobiles, buildings and many other products.

Outcome from the project

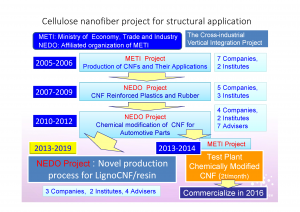

NEDO: Development of the technology for the continuous production process of ligno cellulose nanofibers and their applications for the structural members (2013-)

Hoiroyuki Yano

The fundamental technology to improve the heat resistance of lignocellulose nanofibers and dispersibility of lignocellulose nanofibers in the matrix resins has been developed in order to use cellulose nanofibers to reinforce automotive and housing plastic parts.

Ministry of Environment: Work Entrusted for Evaluating the Performance of Cellulose Nanofibers (Development and Evaluation/Verification of Lightweight CNF Materials for Mainstream Implementation) (2016-)

Arimitsu Usuki, Hiroyuki Yano

This project aims to realize the early social implementation of cellulose nanofibers (CNF), which is expected to contribute to global warming countermeasures, by conducting performance evaluation of composite materials, automotive parts etc. using CNF.

National Agriculture and Bio-oriented Research Organization: Development of soft materials for food and cosmetics applications based on cellulose nanofibers (2015-2016)

Kentaro Abe

This project aims to evaluate the food safety of cellulose nanofibers and to functional soft-materials for food and cosmetics applications using cellulose nanofibers.

NEDO: Development of high performance green nanocomposites for automotive parts by cellulose nanofibers reinforcements.(2010-2012)

Hiroyuki Yano

The fundamental technology to improve the interphase between cellulose nanofibers (CNF) and matrix resins such as high density polyethylene (HDPE), polypropylene (PP) and epoxy resin had been developed in order to use cellulose nanofibers to reinforce automotive plastic parts.

NEDO: Production of chemically modified cellulose nanofibers and their utilization for polymer reinforcement.(2007-2010)

Hiroyuki Yano

The fundamental technology to chemically modify cellulose nanofibers and their utilization to reinforce polyolefin, natural rubber and unsaturated polyester had been developed.

Honda Prize 2016

Hiroyuki Yano (November 2016)

Contributions to the Development of a High-efficiency Production Method of Cellulose Nanofiber (CNF), Its Application to Products, and the Enhancement of Its Potential for Further Utilization

International Nanotechnology Division Awards and Fiber Lean Technologies Prize

Hiroyuki Yano (June 2017, TAPPI)

The development of high efficiency manufacturing process centered on dry-pulp direct kneading method and its application to the construction of test plant.

Test plants for the pulp direct kneading method “Kyoto Process”

Test plants which produces composites reinforced with lignocellulose nanofibers by the integrated production process that simultaneously nanofibrillates the chemically modified dry-pulp and uniformly disperses the CNF in the resins.