2021 Activity Report for Mission 4: Development and Utilization of Wood-based Sustainable Materials in Harmony with the Human Living Environment

Updated: 2022/06/01

Research 1: Innovation of timber structure

Principal Investigator (PI): Hiroshi Isoda (RISH, Kyoto University)

Research collaborator(s): Takafumi Nakagawa (RISH, Kyoto University), Takuro Mori (Hiroshima University), Akihisa Kitamori (Osaka Sangyo University), Yasuhiro Araki (National Institute for Land and Infrastructure Management), Shoich Nakashima(Building Research Institute)

Based on the research for mechanical characteristics of new wooden materials such as cross laminated timber (CLT), we will develop new timber joints and construction system, and evaluate its structural performance which will contribute to the establishment of a sustainable society. We will also promote research on the composite structural members and buildings that combine wooden materials and wooden structures with other materials and structures in order to propose new developments in the use of wood.

Real-sized shaking table test for coupled shear wall 3 story structure using CLT continuous wall with damping system have been carried out to evaluate seismic performance. The numerical analyses for this shaking table specimen have been carried out in order to predict the shaking table tests and to understand the mechanism of the seismic system.

Publications, etc.

- TAKAHASHI Ryudai, YAMAGATA Kaito, INOUE Ryo, MORI Takuro, TSUJI Kento, MATSUDA Masahiro, HORIE Yuichi, TSUJI Takuya, NAKASHIMA Shoichi, ARAKI Yasuhiro, NAKAGAWA Takafumi and ISODA Hiroshi, Shaking Table Tests of Three Story Building using Cross Laminated Timber through Shear Walls with Pre-stress, Proceedings of annual research meeting Chugoku Chapter, Architectural Institute of Japan (AIJ), March 2022

Research 2: Quantitative morphology of woody plants

Principal Investigator (PI): Tomoya Imai (RISH, Kyoto University)

Research collaborator(s): Suyako Tazuru (RISH, Kyoto University),

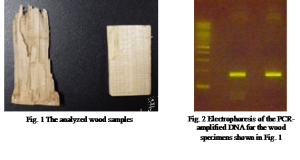

Anatomical inspection is a conventional and reliable way for wood identification with regard to the species. However, there are some difficult cases of species identification only by anatomical inspection. One of such cases is distinguishing between Chamaecyparis obtusa (Hinoki) and Thujopsis dolabrata (Asunaro). This year, we have tested DNA barcode analysis for the samples collected at Chion-In temple in Kyoto (Fig. 1), which was identified as T. dolabrata by anatomical inspection. These samples have been used for more than 100 years as a building material in fact, but DNA amplification in an optimized condition was successful with high reproducibility (Fig. 2). It is then shown that DNA barcode analysis is feasible enough for aged wood. Currently we are further optimizing the protocol for obtaining DNA-sequencing data reliable enough for species identification.

Publications, etc.

- Tomoya Imai, Suyako Tazuru “DNA barcode analysis for identification of wood samples“, The 72nd Annual Meeting of the Japan Wood Research Society, May 15, 2022

Research 3: Understanding internal stress of trees and its utilization

Principal Investigator (PI): Miyuki Matsuo (RISH, Kyoto University)

Research collaborator(s): Kenji Umemura (RISH, Kyoto University), Hiroyuki Yamamoto (Nagoya University), Masato Yoshida (Nagoya University)

Through the growing process, trees accumulate internal stresses in their trunks to control their position and protect them from external forces. This internal stress, called residual stress, is an important survival strategy for trees, but it is also causes deformation of the timber during sawing and reduces production yield.

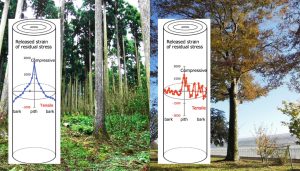

This year, large-scale measurements were carried out to understand the residual stress distribution in large-diameter logs (logs with a diameter of 30 cm or more), where deformation during sawing is a particular problem. Sample trees were Japanese cedar (Cryptomeria japonica) and Japanese zelkova (Zelkova serrata). The residual stresses of cedar los showed a typical bell-shaped distribution (tensile stresses on the bark side and compressive stresses on the pith side), similar to a lot of previous reports. The magnitude of residual stress varied between individuals and, therefore, the deformation of sawn timber was expected to vary between individuals. Young’s modulus, density, diameter and age of the logs were tested as simple indicators for predicting the residual stress of the logs, but none of them were valid. On the other hand, zelkova logs showed a zig-zag pattern along the radial direction, as well as significant variation between individuals. Such a unique distribution has not been reported for any other tree species, with only a few measurements on zelkova, but no mention of the unique distribution. The zig-zag pattern could be related to the pattern of reaction wood formation, but the further investigation was required.

In the future, we will try to find simple indicators to predict the residual stresses of cedar logs. We will also investigate the morphological characteristics of zelkova logs to understand the relationship with the unique pattern of the residual stress.

Figure. Examples of radial distribution of the released strain of residual stress(left: Japanese cedar, right: Japanese zelkova)

Publications, etc.

- Yamashita K, Kato H, Matsuo-Ueda M, Yamamoto H, Measurement of residual stress in large-diameter sugi (Cryptomeria japonica) log using boards with pith, Wood Industry, 76(11), 462-467, 2021

- Matsuo-Ueda M, Tsunezumi T, Jiang Z, Yoshida M, Yamashita K, Matsuda Y, Matsumura Y, Ikami Y, Yamamoto H, Comprehensive study of distributions of residual stress and Young’s modulus in large-diameter sugi (Cryptomeria japonica) log, Wood Science and Technology, 56(2), 573-588, 2022

Research 4:Establishment of environmentally harmonized innovative recycling system of resources in the humanosphere

Principal Investigator (PI): Toshimitsu Hata (RISH, Kyoto University)

Research collaborator(s): Izumi Fujimoto (RISH, Kyoto University), Kazuko Ono (RISH, Kyoto University)

Our research targets are a) to enhance the durability of wood-based materials based on fundamental researches, and b) to research and develop sustainable functional materials from wood. The present research topics are as follows:

(1) Study of mass culture for wood destroying insects

The globalization and acceleration of timber distribution has provided us with cheap wood materials and provided a comfortable living environment. On the other hand, it has also caused the “alien species problem” in which insects attached to overseas products and furniture are brought into Japan without checking and settled. In order to study the control method for newly invaded wood destroying insects, it is indispensable to rear in large scale.

In addition to Coptoremes formosanus and Incisitermes minor, we maintain six species of wood destroying insects such as Lyctus buruneus and L. afuricanus. Lauan, the raw material for artificial diets, became unavailable, and we examined whether or not it could be bred with alternative raw materials. At present, one species grows well, but the other five species have not. We are continuing to study by changing the raw material preparation method.

(2) Investigation of the decay characteristics of hornbeam bamboo

Publications,etc.

- Izumi Fujimoto, Japan Termite Control Association (ed.), “Photo Collection for Field Survey Assistance for Inspection of Ant Damage and Decay,” 24-31, 2021

Research 5: Production and utilization of cellulose nanofibers

Principal Investigator (PI): Hiroyuki Yano (RISH, Kyoto University)

Research collaborator(s): Kentaro Abe, Soichi Tanaka (RISH, Kyoto University)

Cellulose nanofibers (CNFs) are a fundamental component of plant cell walls. Because of their excellent mechanical properties and their high specific surface area, we are studying the utilization of CNFs as a reinforcing filler of resin composites.

In many cases, it is necessary to modify the raw CNFs to obtain a balance between hydrophilic and hydrophobic properties, introduce functional groups, dewater, and re-disperse. Polymer grafting on the surfaces of CNFs is a particularly powerful means of guiding self-assembly and tuning the compatibility of CNFs with other materials. However, large quantities of organic solvent are used in pre-treatment, polymerization, and/or purification, which is environmentally unfriendly. Therefore, there is a demand for new polymer grafting methods that are both facile and green.

In our study, we irradiated an aqueous suspension of CNFs with ultraviolet (UV) light to generate radicals on the sur- faces of the CNFs, initiating polymer grafting. As a result, poly (methyl methacrylate) (PMMA) was readily grafted from the CNFs, without destroying the crystalline region of cellulose. PMMA-grafted CNFs show improved hydrophobicity and redispersibility in organic solvent. As well as PMMA, various other polymers can be grafted from CNFs without using organic solvents. We believe that this technique, called UV grafting, may provide a greener method for producing CNF materials with novel features.

Publications, etc.

- Semba T, Ito A, Kitagawa K, Kataoka H, Nakatsubo F, Kuboki T, Yano H. Polyamide 6 composites reinforced with nanofibrillated cellulose formed during compounding: Effect of acetyl group degree of substitution. Composites Part A: Applied Science and Manufacturing 145, 106385, 2021

- Sato A, Toshimura T, Kabusaki D, Okumura H, Homma Y, Sano H, Nakatsubo F, Kuboki T, Tano H. Influences of dispersion media for chemically modified cellulose nanofibers on rheological and mechanical properties of cellulose nanofiber reinforced high-density polyethylene. Cellulose 28 (8), 4719-4728, 2021