If you would like to participate, please e-mail me your name, affiliation and e-mail address by 10 am on the day.

Registration for Participants

https://us02web.zoom.us/meeting/register/tZEsdeiorD8qHdWbU5nSgfBsqIeriqrZLCG1

(Open Seminar Office: openseminar@rish.kyoto-u.ac.jp)

要旨

The production of wood-based (WBC) and wood-polymer (WPC) composites has been increased considerable over the past few decades due to decreased forest resources and new developments in composite industry. The both composite types, since they enclosed substantial amount of solid wood, are prone decay fungi and termites if utilized without wood preservative treatments especially in outdoor environments. The post-manufacturing treatment is applied after the production of such composites and does not require any modification in composite manufacturing lines while some side effects on mechanical properties are reported. In-line treatments, incorporating biocides during the manufacturing process, might require some modifications on the manufacturing process but provides full protection throughout the board thickness.

The WBC were prepared from five commercially available structural use wood-based composites: softwood plywood (SWP), hardwood plywood (HWP), medium density fiberboard (MDF), oriented strand board (OSB) and particleboard (PB).

Zn-B incorporated particleboards and WPC are produced in RISH and a private company, respectfully. Alkaline copper quat (ACQ), copper azole (CA), accepted as alternatives to Chromated copper arsenate (CCA) worldwide, was used to post-manufacturing treatment of WBC in the current study. Zinc borate (Zn-B) is well accepted worldwide due to its environmentally greener record and high thermal stability was chosen for in-line treatment of PB and WPC.

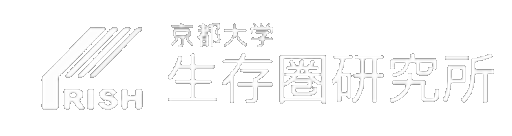

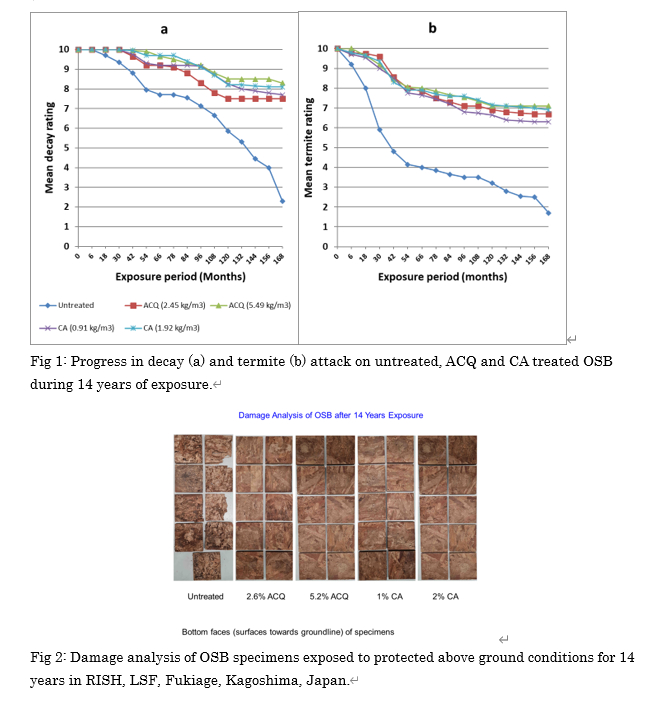

The 100mm x 100mm specimens were prepared and installed in the Living-sphere Simulation Field (LSF) in a plantation forest in Fukiage, Kagoshima Prefecture in south-east Japan. A previously developed system to simulate performance of sill plates (dodai) in traditional Japanese homes was used in the field test. All specimens were visually inspected biannually around October and May according to AWPA E-21 standard on a scale from 10 to 0 for both decay and termite attacks during 14 years.

The field test result indicated that termite damage started earlier and the severity of attack was always higher regardless of composite types. The untreated controls wood-are not durable enough, even in protected above ground conditions, if they are used without protective treatment, with the exception of MDF. MDF displayed high natural durability and might be used under less hazardous conditions. . Post treatment with ACQ and CA at the retention levels tested significantly enhanced termite resistance of SWP, HWP, OSB and PB but failed full protection at the end of test period.

While incorporation of ZnB during production of PB did not cause any mechanical property losses, durability of PB against decay and termite activity notably increased. After 14 years of exposure, ZnB PB specimens were able to hold highest decay (10) and termite (8.5) resistance among all tested specimens. ZnB integrated WPC had slightly lower resistance than ZnB-PB but after first 4-5 years some decay activity observed.

portable document format file(216,920byte) |

2023年7月3日作成