210th Regular Open Seminar

Long-term field test performance of treated wood-based and wood-plastic composites (WBCs and WPCs)

| 開催日時 | 2016-09-21 12:30–13:20 |

|---|

Presenter: Cihat Tascioglu (Professor, Duzce University, Faculty of Forestry, Duzce, Turkey, currently Visiting Professor at RISH, Kyoto University)

Title: Long-term field test performance of treated wood-based and wood-plastic composites (WBCs and WPCs)

Place: HW525 (Research Building No. 1)

Related Mission: Mission 4 (Development and Utilization of Wood-based Sustainable Materials in Harmony with the Human Living Environment)

Summary

The production of wood-based and wood-plastic composites (WBCs and WPCs) has increased considerably over the past few decades and they have been utilized under conditions conducive to biological attacks. Unfortunately, these composites are prone to decay fungi and termite attacks if utilized without preservative treatments. There are two major procedures to protect WBCs and WPCs. The post-manufacturing treatment is applied after the production of such composites and does not require any modification in composite manufacturing lines while some side effects on mechanical properties are reported. In-line treatments, incorporating biocides during the manufacturing process, might require some modifications on the manufacturing process but provides full protection throughout the board thickness.

Alkaline copper quat (ACQ) and copper azole (CA) which have been accepted worldwide as alternatives to chromated copper arsenate (CCA), were evaluated as wood preservatives for post-manufacturing treatment of WBC in the present research. Zinc borate (ZnB) and sodium fluoride (NaF) are chosen for their low environmental impact profile and high thermal stability for particleboard and WPC production.

Specimens were prepared from five commercially available structural-use wood-based composites: softwood plywood (SWP), hardwood plywood (HWP), medium density fiberboard (MDF) produced from hardwood fibers, aspen oriented strand board (OSB) and particleboard (PB) made of both hardwood and softwood particles. The specimen sizes were 210 mm × 30 mm × thickness and 100 mm × 100 mm × thickness for laboratory and field tests, respectively. ACQ and CA were tested for their effectiveness at three retentions, respectively K1, K2 and K3 classes as designated by JAS. Zinc borate and sodium fluoride were added at 1, 1.5 and 2 % and 1, 1.5, 2 and 3 % as w/w levels, respectively, during the manufacturing of particleboards. The WPCs are also produced in the same manner (in-line process) but at lower retention levels.

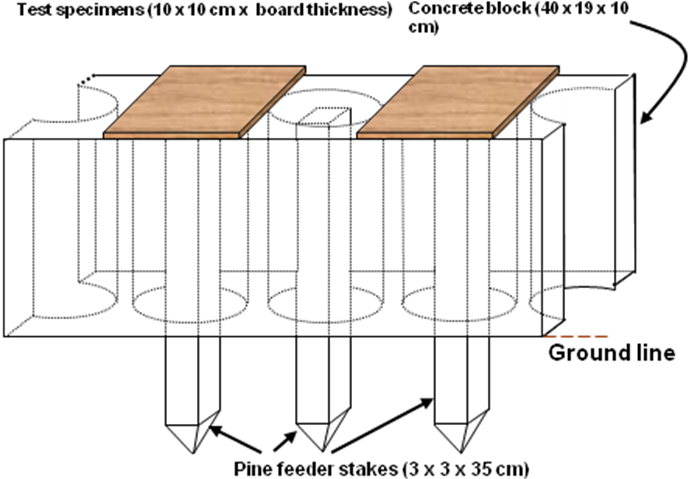

Untreated and treated wood based composite specimens were tested for their changes in mechanical properties due to preservative treatments by the JIS three-point bending method. A previously developed system to simulate performance of sill plates (dodai) in traditional Japanese homes was used in the field tests.

Fig. 1. Installation details of specimens and feeder stakes in the Living Sphere Simulation Field (LSF) of RISH, Kagoshima, Japan.

The findings indicate that wood-based composites tested are not durable enough, even in protected above ground conditions, if they are used without protective treatment, with the exception of MDF. MDF displayed high natural durability and might be used under less hazardous conditions based on 7-year exposure data. Post treatment with ACQ and CA at the retention levels tested significantly enhanced termite resistance of SWP, HWP, OSB and PB but failed full protection at the end of 84 months period.

While zinc borate incorporation retentions tested in this experiment were successful to protect PBs from decay damage for 84 months, higher than 2 % w/w retentions are needed to provide full protection against termite activity under protected above ground conditions in southern Japan.

WPCs used regardless of formulation, wood particle size, surface grooving and zinc borate content shoved greater resistance to decay activity during exposure period with the exception of last 18 months where even the ZnB embedded formulations started to exhibit reducing decay ratings. It is clear that ZnB retentions slow down termite damage even in higher wood content formulations, higher ZnB retentions (above 1 % w/w) are required for better protection.

Go to Japanese page

PDF file (81 645 bytes) | Top

September, 2016.