Presenter: Soichi Tanaka (Mission Research Fellow, RISH Kyoto University)

Title: Solute diffusion into cell walls in solution-impregnated wood during conditioning process

Place: HW525 (Research Building No. 1)

Associated Mission: Mission 4 (Development and Utilization of Wood-based Sustainable Materials in Harmony with the Human Living Environment)

Summary

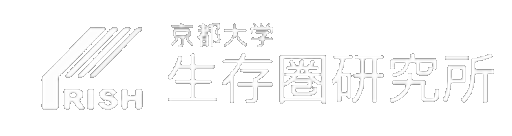

Wood flow forming is a new wood processing technique that has recently been developed. The flow-formed wood is known to have far higher bending strength than wood block and conventional wood-based materials. In this technique, bulk wood is processed into the compact with a favorite form by being compressed and flowed into a metal mold (Fig. 1).

Fig. 1 Wood flow forming process.

The compact whose raw material was not chemically treated, however, decomposed if the compact was soaked in boiled water for 1 hour (Fig. 2). Therefore, the wood raw material before compressed is required to be chemically treated, to obtain a stable compact by preventing the unstable amorphous structure in cell walls from absorbing water and from becoming the origin of decomposition.

Fig. 2 Unstable compact composed of raw material without chemical treatment.

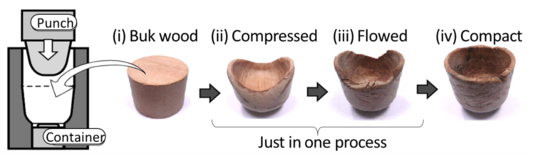

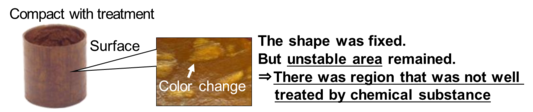

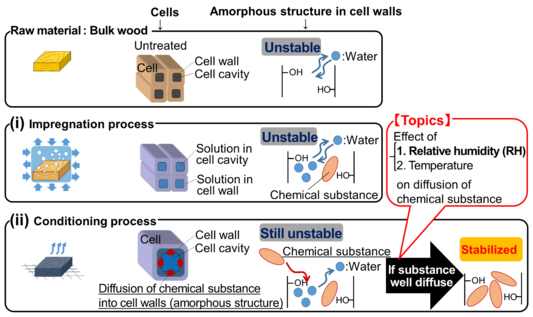

In the chemical treatment, the wood raw material was impregnated by a solution of chemical substance and subsequently conditioned to evaporate solvent (Fig. 3). In the compact whose raw material was chemically treated, however, the unstable region still remained (Fig. 4).

Fig. 3 Chemical treatment of wood raw material before flow forming process.

Fig. 4 Color change in compact composed of raw material with chemical treatment.

This was considered to be due to the presence of the cell walls that was not well chemically treated in the bulk wood before compressed. Thus, it is necessary to control the chemical treatment so that the cell walls in the raw material are adequately filled with the chemical substance.

In my study, the conditioning process (Fig. 3(ii)) was noticed as the important process in which the untreated amorphous structure may stabilize (Fig. 5). Just before the conditioning process (Fig. 5(i)), in the amorphous structure in cell walls, there exists not only the chemical substance but also the solvent, which causes the unstable state of the amorphous structure. Under some atmospheric state in the conditioning process (Fig. 5(ii)), chemical substance is suggested to diffuse from cell cavities into cell walls and replaces the solvent in cell walls (A. J. Stamm (1956) Forest Products Journal, Vol. 6, No. 5, pp. 201–204). The appropriate state, relative humidity (RH) and temperature, under which the substance is well diffused and replace the solvent, however, has not yet been clarified. If the atmospheric state was well controlled, it was expected that chemical substance will well diffuse into cell walls and replace the solvent in cell walls, and thus cell walls will adequately filled with chemical substance.

In this seminar, the effect of RH in the conditioning on diffusion of chemical substance into cell walls will be introduced when the polyethylene glycol (PEG 1540) is employed as chemical substance.

Fig. 5 Importance and topics of conditioning process for treating the unstable amorphous region adequately with chemical substance.

Go to Japanese page

PDF file (1 295 390 bytes) | Top

22 July, 2016.