e-ASIA Joint Research Program "Alternative Energy" (Bioenergy)

Background

Sugarcane Trash (ST) is an excellent and underused biomass resource in sugar-producing countries worldwide. However, only a small quantity of ST is used as fuel, mixed with bagasse or by itself, at the sugar mill. The rest is burned in the vicinity of the dry cleaning installation, creating a pollution problem in sugar-producing nations.The development of the utilization of this potent lignocellulosic waste in Southeast Asia (SEA) will lead to improved energy security and self-dependency of Japan and SEA countries.

Research

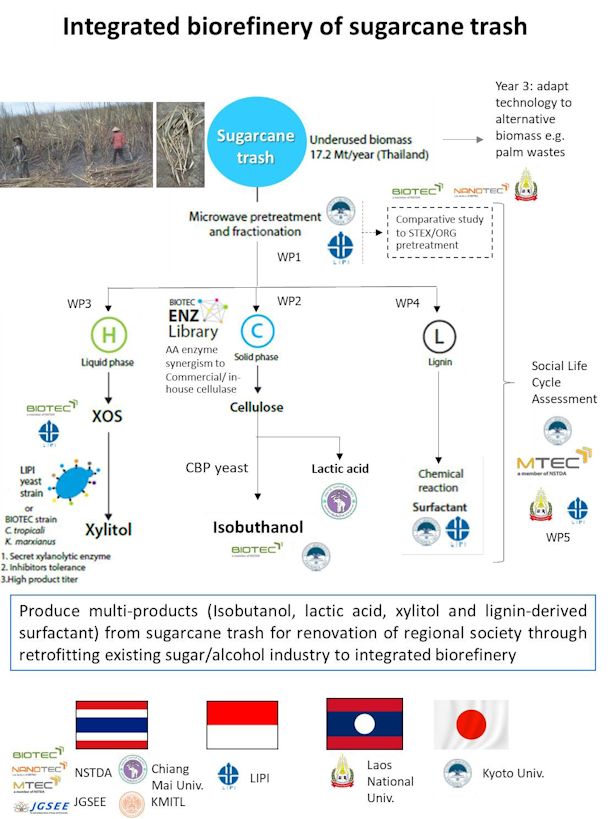

This collaborative research aims to provide a model for retrofitting existing sugar mills and ethanol plants by transforming them to biorefinery complex with useful multi-products, leading to improved economic and environmental benefit.

Specifically, the Japanese research team will develop microwave-assisted separation technology suitable for the production of multi-products from sugarcane trash by analyzing chemical structures. The team will analyze the economic and social impact of the integrated process. Thai team will develop efficient lignocellulose-degrading enzymes, design yeast cell factory by synthetic biology, and develop bioprocess for production of lactic acid and isobutanol. Indonesia team will study lignin-derived surfactants and production of xylitol. Laos team will study physicochemical pretreatment of sugarcane trash for biogas production.

Through collaborative and complementary research among 4 countries, this research is expected to provide a platform for development of cost-effective biomass fractionation technology, robust cell factory and efficient chemical processing for conversion of cellulosic feedstocks to chemicals.